Part 2 - The Beating Heart of Your Watch

Share

A Deep Dive into Mechanical Movement Mechanics

Welcome back! In Part 1 , we explored Quartz and Solar Quartz movements. Now, we'll continue our journey into the fascinating world of watchmaking by delving into the intricate mechanics of manual wind and automatic movements, and why they are at the core of Brigade Watch Company's commitment to quality.

3. Mechanical Movements Manual Wind

Image 2: Mainspring, Barrel, and Barrel Arbor Components

How it Works: A Dance of Gears and Springs

This is horology in its purest form - no batteries, just intricate mechanical cleverness. It's all about how energy is stored and then carefully released.

Winding the Power (Mainspring & Barrel): When you turn the watch's crown (the little knob on the side), rotational forces transfer through the crown stem and tiny gears to the barrel arbor. This arbor is the central rod around which the mainspring is coiled. The mainspring itself is a long, flat piece of metal ribbon, coiled tightly inside a round container called the barrel. Its inner end hooks securely to the barrel arbor, and its outer end typically hooks to the inside wall of the barrel. As you wind the crown, the barrel arbor turns, tightening the mainspring inside its barrel—imagine winding up a toy car's spring before letting it go, or tightening a giant coil inside a drum. This action stores potential energy.

Image 3: Mainspring Hooks and Details

Power Transfer to the Gear Train: As the mainspring slowly unwinds, it exerts force on the barrel, causing it to turn. The teeth on the outside of the barrel engage with the first gear of the gear train. This gear train is a series of interconnected wheels and tiny pinions (small gears) that transmit the power from the mainspring and carefully increase the speed as it moves towards the escapement. Each wheel turns a pinion, which turns the next wheel, and so on.

Image 4: Watch Gear Train and Coiled Mainspring

Timekeeping (Escapement, Balance Wheel, Hairspring): The final part of the gear train connects to the escapement, which is the absolute heart of the watch's accuracy. Imagine a tiny, perfectly timed gatekeeper inside the watch. This 'gatekeeper' is a clever assembly made of the toothed escape wheel (the smaller spiked wheel in the image below) and the pallet fork (the trident-shaped component), which has two tiny pallet jewels (usually synthetic rubies) on its arms. The escape wheel tries to spin continuously, pushed by the mainspring's power, but the pallet fork's jewels "catch" and "release" its teeth one by one in precise, tiny bursts. Each "release" gives a small push to the balance wheel (the larger golden wheel below), causing it to swing back and forth.

Image 5: Escapement Components: Escape Wheel, Pallet Fork, and Balance Wheel

Steady Rhythm: Connected to the balance wheel is a very fine, spiraled wire called the hairspring. The hairspring acts like a tiny spring that makes the balance wheel oscillate at a very steady rate (e.g., 28,800 VPH for a modern watch). This consistent swinging of the balance wheel, precisely regulated by the escapement's steady releases, is what truly keeps time. Each "tick-tock" you hear is the escapement doing its job!

Moving the Hands: The regulated energy from the escapement is then sent back through parts of the gear train, causing the watch's hands to move precisely around the dial.

Pros and Cons of a Manual Wind Movement:

Pros:

- Traditional Craftsmanship: Represents the purest form of watchmaking, highly valued for its intricate engineering and historical significance.

- Intimate Connection: The daily ritual of winding creates a personal bond between the wearer and the timepiece, a moment of connection with a complex machine.

- No Battery: Environmentally friendly and highly sustainable due to not requiring harmful batteries.

- Timeless & Prestigious: Highly valued for its engineering and traditional appeal, often considered an investment piece.

- Most Eco-Friendly: Mechanical watches are the most eco-friendly—even more than solar movements—because they operate without batteries and, when properly serviced, can last for decades or even centuries. In contrast, solar watches still rely on rechargeable batteries that eventually need replacement, making them less sustainable in the long run.

- Thinner Profiles: Often allows for slimmer watch cases compared to their automatic counterparts because they don't need space for an automatic winding rotor.

Cons:

- Requires Manual Winding: If not wound on a constant basis (usually once every 24-48 hours), the watch's mainspring will lose tension causing timekeeping to stop.

- Less Accurate than Quartz: Generally speaking a mechanical movement is less accurate than a quartz / battery movement due to sensitivity to things like gravity, temperature changes, and even small bumps.

- Requires Servicing: Needs professional servicing every 5-7 years to clean, lubricate, and ensure optimal function, similar to maintaining a high-performance engine.

Image 6: Disassembled Automatic Wind Mechanical Movement

4. Automatic Mechanical Movement: The Self-Winder

How it Works: Power from Your Movement

An automatic movement builds on the manual wind design, adding a brilliant feature: it powers itself using your everyday motion.

Kinetic Power (The Rotor): The key difference is the oscillating weight (rotor) – a crescent-shaped metal weight, often visible through a clear case back. Similar to how a playground merry-go-round spins as you push it, the rotor spins freely with your wrist's natural motion (walking, gesturing, etc.).

Image 7: Automatic Movement Rotor

Self-Winding Mainspring: As the rotor spins, it engages a small set of gears that, in turn, automatically wind the mainspring inside its barrel. This continuously adds energy to the mainspring as long as the watch is worn.

Preventing Overwinding (The Slipping Bridle): Here’s a crucial difference from a manual-wind watch:

- In a manual-wind watch, the mainspring is firmly hooked to the inside wall of the barrel. Once it's fully wound, you can't wind it anymore without risking damage.

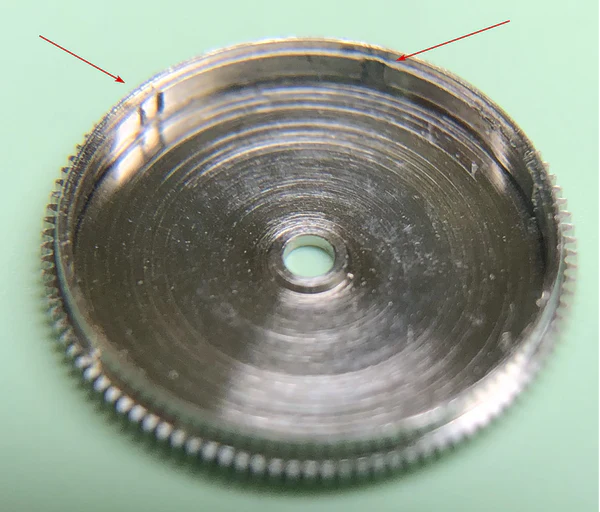

- In an automatic movement, the outer end of the mainspring is attached to a special mechanism called a slipping bridle (also known as a friction bridle) inside the barrel. Once the mainspring is fully wound, this bridle is designed to slip gently against the barrel wall. In some older automatic watches, the inner wall of the barrel was entirely smooth. In contrast, many modern automatics feature a series of notches along the inner barrel wall, designed to help the outer coil of the mainspring grip more effectively — remember the outer coil still needs to grip to be able to be wound.

- Imagine a fishing reel that lets out line when the fish pulls too hard, even if you're trying to reel it in. This clever slipping mechanism allows the rotor to continue spinning and attempting to wind the mainspring without causing it to break due to overwinding. If an automatic movement used a standard manual-wind barrel (where the mainspring is rigidly fixed), the continuous winding from the rotor would quickly try to wind the spring beyond its capacity, causing it to snap.

Image 8a: Diagram of Mainspring with Slipping Bridle

Image 8b: The Red Arrows Point to the Notches on the Automatic Movement's Barrel

The Rest is Mechanical: Once the mainspring is wound (either fully or partially), the rest of the process is identical to a manual wind watch: the power flows through the gear train to the escapement, which then regulates the steady swing of the balance wheel and hairspring, driving the hands.

Pros and Cons of a Automatic Wind Movement:

Pros:

- Self-Winding Convenience: No batteries and no daily manual winding needed as long as the watch is worn regularly. It's always ready to go.

- Artistry & Craftsmanship: Embodies the same intricate mechanical beauty as manual-wind watches, often made visible through an exhibition case back, allowing you to admire the complex machinery.

- Timeless & Prestigious: Highly valued for its engineering and traditional appeal, often considered an investment piece.

- Heirloom Potential: Mechanical movements are robustly designed to last for generations with proper care and servicing.

- Most Eco-Friendly: Mechanical watches are the most eco-friendly—even more than solar movements—because they operate without batteries and, when properly serviced, can last for decades or even centuries. In contrast, solar watches still rely on rechargeable batteries that eventually need replacement, making them less sustainable in the long run.

Cons:

- Less Accurate than Quartz: While excellent, they typically won't match the pinpoint accuracy of a quartz watch over long periods due to their mechanical nature.

- Thicker Watch Cases: The rotor mechanism usually makes the watch slightly thicker than a manual-wind or quartz watch.

- Requires Servicing: Like manual-wind movements, periodic professional servicing (every 5-7 years) is essential to clean, lubricate, and ensure longevity.

- Higher Initial Cost: Generally, the most expensive movement type to purchase.

Image 9: Luxury Automatic Watch Movement

Why does Brigade Use Mechanical Movements

At Brigade Watches, our use of the Swiss Automatic -Elaboré grade Sellita SW200-1 movements is central to our commitment to quality and value. While we could opt for cheaper alternatives, these proven "workhorse" movements are trusted for their reliability and longevity.

Image 10: ETA - 2824

Reliable Performance & Proven Heritage: These Swiss movements have a decades-long track record of durability and accuracy. Built on time-tested engineering, they ensure your Brigade watch remains dependable for years to come.

Enhanced Accuracy & Precision: We select the Elaboré grade for its superior finishing and, critically, tighter factory regulation. Furthermore, these movements are adjusted to 3 positions. Imagine getting a high-performance car tuned so it runs perfectly whether it's driving uphill, downhill, or on a flat road. This critical step ensures the watch's precision is maintained across various orientations it experiences during daily wear, significantly minimizing the effects of gravity on the balance wheel. The result? A watch that keeps more consistent and accurate time on your wrist.

Craftsmanship with Soul: Each automatic movement contains hundreds of incredibly tiny, precision-made parts, often adorned with traditional finishes. These movements are then hand-assembled by highly skilled watchmakers, often requiring specialized tools and years of training. This intricate, labor-intensive process is an art form, providing your watch with a tangible "soul" that an electronic watch cannot replicate.

Image 11: A watchmaker assembling a mechanical movement by hand.

Serviceability & Lifelong Value: Because these movements are widely used, parts are readily available, and watchmakers globally are familiar with them. This ensures your Brigade watch can be easily serviced and maintained throughout its life, allowing it to become a cherished heirloom passed down through generations. It's not just a purchase; it's an investment in enduring quality.

Swiss Made Legacy: Choosing these movements directly links Brigade Watches to the unparalleled legacy of Swiss watchmaking—a benchmark for quality, precision, and innovation. This guarantees a superior product, crafted under the highest standards.

Image 12: Swiss Automatic Movement (Sellita SW200-1)

What Truly Makes Mechanical Watches More Expensive?

The cost of automatic mechanical movements, especially high-quality Swiss movements Brigade uses, is a direct reflection of several key factors that set them apart from their electronic counterparts:

- Extreme Complexity & Number of Parts: A typical automatic mechanical movement contains anywhere from 100 to over 300 tiny, intricate components (gears, springs, levers, screws, jewels). Each part must interact perfectly with the others. Contrast this with a quartz movement, which might have only a few dozen parts, many of which are electronic and solid-state.

Image 13: Disassembled mechanical watch movement showcasing numerous parts

- Precision Micro-Manufacturing: Creating these miniature components requires incredibly advanced machining techniques to achieve micron-level tolerances (meaning, measurements smaller than a human hair). Every gear, pivot, and spring must be manufactured with extreme accuracy to ensure smooth, efficient operation.

- High-Grade Materials: Mechanical movements utilize specialized metal alloys for springs and gears, chosen for their durability, anti-magnetic properties, and resistance to temperature changes. Crucially, they also incorporate jewel bearings (tiny synthetic rubies) at friction points. These jewels are incredibly hard and smooth, significantly reducing wear and tear on moving parts, extending the movement's lifespan dramatically.

Image 14: Gold Plated Mechanical Movement

- Skilled Craftsman (Assembly & Finishing): This is perhaps the biggest factor. Unlike the largely automated assembly of quartz movements, mechanical movements are predominantly hand-assembled by highly trained watchmakers. Each tiny screw, gear, and spring is carefully placed and aligned. Beyond assembly, components are often hand-finished (e.g., polishing, bevelling edges, applying decorative patterns like Côtes de Genève). These finishes are not just aesthetic; they reduce friction, improve efficiency, and make the parts more durable. This level of craftsmanship is irreplaceable by machines.

Image 15: Components of our SubCommander

- Intensive Regulation & Adjustment: Achieving accuracy in a mechanical watch requires meticulous regulation. Watchmakers spend considerable time adjusting the movement, sometimes for days, testing it in different positions and temperatures, to fine-tune its rate. This delicate art ensures the watch keeps time as precisely as possible.

- Designed for Longevity & Serviceability: Mechanical movements are built with the intention of lasting for generations. This means they are designed to be fully disassembled, cleaned, lubricated, and reassembled – a complex process that extends their life indefinitely. The upfront cost includes this inherent design for enduring performance.

In essence, our commitment to these high-quality Swiss automatic movements allows us to offer you a watch that balances cutting-edge precision with enduring beauty and profound craftsmanship. It's why a Brigade watch isn't just an item you wear; it's a piece of horological art that tells a story of passion and excellence.