Navigation at Sea: Marine Chronometer

Share

Navigation at Sea: The Marine Chronometer

For us at Brigade Watch Company, a timepiece is more than just minutes and hours; it's a testament to innovation, resilience, and purpose. Today, let's uncover the incredible story of the marine chronometer-an invention that revolutionized sea navigation, established military timekeeping, and directly influenced the dive watches we proudly create and wear.

Lost at Sea: The Deadly Mystery of Longitude

Imagine being on the vast, open ocean, with nothing but the horizon in every direction. How would you know where you were? For centuries, sailors grappled with this terrifying dilemma. Determining their latitude (north-south position) was relatively straightforward. They could measure the sun's angle at noon, a method effective in both hemispheres. In the Northern Hemisphere, they also used the North Star (Polaris) by measuring its angle from the horizon at twilight. But pinpointing their longitude (east-west position) remained a massive, often deadly puzzle.

Think of it like this: The Earth is a giant spinning ball. As it spins, different regions experience noon at different times. If you know the exact time at a known starting point (such as a port in England) and you know the exact local time where your ship is (which you can find when the sun is highest in the sky at noon), the difference between those two times tells you how far east or west you've traveled. Every 15 degrees of longitude around the Earth's circumference equals one hour's difference in time. So, if your local noon happens three hours after noon in England, you know you're 45 degrees west of England (3 hours × 15°/hour). Simple, right?

The catch? Before the marine chronometer, there was no time keeping device that could keep accurate time on a ship. Regular clocks or watches of the time were incredibly unreliable at sea. They were easily thrown off by the constant rocking and rolling of the ship, the changing temperatures from day to night and from the tropics to colder waters, and the damp, salty air. A clock that was even a few minutes off could mean being hundreds of miles off course. This wasn't just an inconvenience; this meant ships could run aground on uncharted coastlines, get lost in storms, or miss vital trade routes-costing countless lives. This was "the longitude problem," and it was one of the biggest scientific challenges of the 18th century.

Enter John Harrison

Governments were desperate for a solution and offered huge rewards. Following the devastating 1707 shipwreck off the Isles of Scilly, in which four British naval vessels were lost due to a navigational mistake the British Parliament issued the Longitude Act. Parliament offered the colossal amount of £20,000 (£5 million today) to anyone who could devise a reliable way to determine longitude while at sea within half a degree of accuracy. Many brilliant scientists and astronomers believed the answer lay in observing the moon and stars, creating complex tables. But one man dared to think differently: John Harrison.

Born in 1693 in a small village in Yorkshire, England, John Harrison the son of a carpenter was largely self-taught. From a young age, he showed an incredible mechanical talent, particularly with clocks. He actually started his career building massive, intricate clocks made primarily of wood for local churches.

Harrison understood the fundamental flaws of existing clocks when used on a ship:

-

- 1. Pendulums don't work on a ship: Pendulums swing back and forth based on gravity, so they need a perfectly stable surface. A ship pitching and rolling rendered them useless.

-

- 2. Temperature changes: Metal parts in clocks expand when hot and contract when cold. This tiny change in size could speed up or slow down a clock significantly over days or weeks.

-

- 3. Friction: The tiny rubbing of gears and pivots could slow a clock down, especially as lubricants would dry out or change consistency with temperature.

-

- 4. Corrosion and humidity: Saltwater and dampness are terrible for delicate clock mechanisms because they cause corrosion, rust, and swelling in metal and wooden components, which can disrupt precision and lead to mechanical failure.

Harrison believed, with an almost stubborn conviction, that a purely mechanical timekeeper, if designed ingeniously enough, could overcome all these problems. He decided to dedicate his entire life to this singular goal, turning down other opportunities and pouring every ounce of his ingenuity into solving the longitude problem with a clock. His motivation wasn't just the prize money (though that certainly helped!), but a deep passion for precision and a desire to contribute something truly revolutionary.

Harrison's Revolutionary Chronometers

Harrison's journey was long, arduous, and filled with incredible invention. He didn't just tweak existing clock designs; he invented entirely new mechanisms that had never been seen before. He built a series of timekeepers, each an improvement on the last:

H1 (1735):

His first sea clock was made in 1735. It was a giant, intricate machine that took Harrison five years to build. It was large and enclosed in a bulky case and filled up much of the captain's tiny cabin. Instead of a pendulum, it used two big linked dumbbell-shaped balances designed to counteract the rolling and pitching of a ship. On its sea trial to Lisbon, H1 performed impressively, helping correct the ship's longitude on the return leg and possibly preventing disaster. Even with that success, Harrison wasn't satisfied. He saw room for improvement and knew the design was still too large and complex for practical use at sea. On land, it was accurate to within several seconds per day.

H2 (1737-1739):

This was a larger and more robust version of H1, built with greater solidity and refinement. Harrison incorporated a remontoire, a clever mechanism that delivered a more constant and uniform power supply to the escapement, regardless of how much the mainspring had wound down. He also introduced improved temperature compensation, aiming to boost accuracy even further. But despite these advancements and rigorous testing on land, Harrison never allowed H2 to be tested at sea because he discovered a fundamental design flaw. The clock was still vulnerable to errors caused by sharp, sudden forward-and-backward movement, exactly the kind of motion a ship endures. In his relentless pursuit of perfection, he decided not to risk failure at sea. Instead, he abandoned H2 and started again from scratch on a new design.

H3 (1759):

The H3 iteration built upon everything Harrison had learned from H1 and H2. It took him nearly 19 years to complete, and by then he was in his late 60s. H3 kept many of the features of its predecessor but swapped out the dumbbell balances for a pair of linked circular balances, which were meant to improve stability.

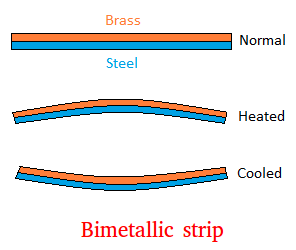

It also introduced two groundbreaking innovations: the bimetallic strip for temperature compensation, and the caged roller bearing, which minimized friction-both of which are still in use today.

Despite all this ingenuity, H3 never went to sea. Harrison realized it still wasn't accurate enough for the harsh conditions of ocean travel. Yet again Harrison set it aside and started fresh, this time with a radically different idea that would become his masterpiece: H4.

H4 (1761):

Then came the H4, the version that changed everything. Unlike Harrison's earlier, larger creations, the H4 was remarkably compact, almost the size of a pocket watch, and weighed a mere three pounds. This miniaturization was a marvel of engineering.

On its maiden voyage to Jamaica, the H4 performed with astonishing accuracy. After an 81-day journey, it determined longitude with an error of only 1.5 minutes of arc, far exceeding the Longitude Act's requirements!

How It Works: The Mechanics Behind the H4 Marine Chronometer

The extraordinary accuracy of John Harrison's H4 marine chronometer stemmed from a masterful blend of mechanical innovations. Each feature was meticulously engineered to address the unique challenges of timekeeping aboard a moving ship-from violent motion to fluctuating temperatures and variable humidity. What emerged wasn't just a clock-it was a self-regulating marvel of 18th-century engineering.

Temperature Compensation (The Bimetallic Strip):

Imagine a tiny metal spring inside a timepiece. When it gets hot, this spring expands and gets longer, which makes the timepiece run slower. When it gets cold, it shrinks, making the timepiece run faster. Even a tiny change in temperature could throw a timepiece off by minutes over a long voyage.

Harrison's brilliant solution was the bimetallic strip. This tiny, delicate component is made of two different metals, such as brass and steel, bonded firmly together. When exposed to changes in temperature, these two metals expand and contract at different rates. Because they're fused, this differential movement causes the strip to bend rather than simply stretch or shrink evenly.

Harrison's ingenious solution involved carefully integrating these bimetallic strips into the balance wheel-the component that swings back and forth like a tiny pendulum. The strip would be attached to a small lever or regulator arm near the hairspring.

As the bimetallic strip bends with temperature fluctuations, it subtly adjusts the hairspring's effective length or tension. When it's hot, the strip bends inward, making the spring shorter, which causes the watch to tick faster. This counteracts the natural slowing effect of heat. Conversely, when cold, the strip bends outward, lengthening the spring and slowing the ticks, offsetting the speeding caused by cold. This clever bending perfectly counteracted the natural expansion or contraction of the hairspring, ensuring consistent timekeeping. It's like the chronometer had its own built-in, microscopic thermostat, constantly fine-tuning itself!

Isochronism (The Steady Beat of the Balance System):

This fancy word simply means "equal time." For a clock to be accurate, its swinging part (the balance wheel) must always take the exact same amount of time for each complete swing, no matter how big or small that swing is. If the swings aren't precisely equal, the timekeeping won't be accurate.

Harrison dedicated immense effort to achieving this. The balance wheel and balance spring work together as the "heartbeat" of the watch.

- Balance Wheel: Harrison's balance wheels, especially in his later models, were designed for perfect poise (meaning their weight was perfectly balanced around their center) and minimal air resistance. While early balance wheels were often simple metal rings, Harrison innovated with complex, cut bimetallic balances (the very strips discussed above) that effectively changed their shape with temperature to maintain a consistent moment of inertia. For materials, they would typically be made of metals like brass and steel (for the bimetallic compensation) or later, specialized alloys for stability.

- Balance Spring (Hairspring): This is a tiny, incredibly fine coiled spring that provides the restoring force, bringing the balance wheel back to its center position after each swing. For perfect isochronism, this spring needed to have a consistent elasticity, regardless of temperature or how much it was uncoiled. Harrison was among the first to use hardened and tempered steel for balance springs, which offered far greater stability than the raw steel or even gold used by others at the time. This specific treatment of the steel made it much more resilient and less prone to "fatigue" or losing its elasticity over time, which would cause the clock to slow down.

Gimbal Mounting (Staying Level):

Even with all the internal genius, a ship violently pitching, rolling, and yawing could still affect the chronometer. The solution was surprisingly simple yet brilliant: the gimbaled box. The chronometer itself was placed inside a series of concentric rings, much like a gyroscope. This clever suspension system ensured that the chronometer remained perfectly level and upright, regardless of how much the ship moved. Imagine a compass that always stays flat even if you tilt the boat – that's the principle. This ensured the delicate timekeeping mechanism was always operating in its intended, stable orientation.

The Grasshopper Escapement (The Frictionless Dance):

While not used in the final H4 model, the grasshopper escapement deserves mention as one of John Harrison’s most original and elegant inventions—deployed in his earlier marine timekeepers H1 through H3 — H4 was made with a type of refined verge escapement. Invented by John Harrison in the early 18th century, the grasshopper escapement was a groundbreaking solution to a centuries-old problem: how to transfer energy to a pendulum or balance without introducing friction or disrupting its natural rhythm.

In a mechanical timepiece, the escapement is what releases stored energy from the mainspring or weight-driven gear train in small, timed bursts. This keeps the oscillating part (like the pendulum or balance wheel) moving steadily.

Traditional escapements relied on sliding contact between parts, which caused wear and required frequent lubrication—problematic on long sea voyages where temperature changes broke down oils. Harrison’s genius was in creating an escapement with virtually no sliding friction.

Here’s how it worked:

- • It used two hinged, lightweight arms (pallets) that alternately engaged the teeth of the escape wheel.

- • As the pendulum swung, one pallet would momentarily lock the wheel, while the other was lifted by the motion of the pendulum and delivered a quick, efficient impulse.

- • Then they’d switch roles—hence the name “grasshopper,” as the pallets resemble insect legs snapping in and out.

Harrison’s Award:

Despite H4's undeniable success and its proven ability to save lives, Harrison faced incredible resistance. One of Harrison’s chief opponents was Nevil Maskelyne, the Astronomer Royal and a key figure on the Board of Longitude. As a strong advocate for the lunar distance method, Maskelyne had his own stake in the prize and was reluctant to acknowledge the success of Harrison’s timekeepers. As a result, despite the remarkable performance of his H4 chronometer, Harrison received only a portion of the promised reward—just a few thousand pounds.

Determined to secure full recognition, Harrison and his son later built H5, a chronometer that retained the intricate mechanics of H4 but featured a more streamlined design. During a five-month sea trial to Barbados, H5 demonstrated outstanding accuracy, deviating by only about 15 seconds. Eventually, in 1773—after decades of struggle and at the age of 80—Harrison was awarded the remainder of the prize, thanks in large part to the personal support of King George III.

From Navigational Lifesavers to Combat-Ready Timepieces

The marine chronometer represents one of the earliest and most critical applications of precision horology in a military context. Its role in enabling global naval power, allowing fleets to navigate accurately, coordinate attacks, and establish vast empires cannot be overstated. This incredible lineage of military-grade, reliable timekeeping is precisely where Brigade Watch Company finds its inspiration.

The need for robust, reliable timekeeping for military operations continued to evolve. As naval warfare shifted and new challenges emerged, the demand for specialized watches grew. The direct descendant of the marine chronometer's spirit of unwavering precision and durability in harsh environments can be clearly seen in the development of military dive watches. These watches, designed for underwater operations by navies around the world, share the chronometer's core principles: extreme legibility (easy to read in any condition), exceptional water resistance, superior shock protection, and unwavering accuracy under the most demanding conditions. They are, at their heart, tools designed for survival and mission success, just like Harrison's chronometers.

At Brigade Watch Company, we honor this incredible legacy. Our watches are crafted with the same dedication to precision, durability, and functional design that defined the marine chronometer. We ensure they are ready for whatever mission lies ahead – whether on land, in the air, or deep beneath the waves. We build timepieces that stand the test of time, just like John Harrison's incredible, life-saving inventions.